Lately I’d been having a problem with my gaming mouse, A4Tech X7 XL-750BF. It had been making weird jumps while using the scrolling wheel. It is a relatively expensive mouse for throwing out and buying a new one, even it is three years old. When I was googling for a solution, I’ve found out that it is a general problem with A4Tech mice. Too little or dried off lubricant from the factory causes malfunction as the time goes by. But there is a cheap and easy solution for it: petroleum jelly a.k.a. pure vaseline. You can easily get it from a pharmacy.

In this post I’ll be telling how I fixed it with pictures. Click them to view full-size. I now have a mouse like the day I bought it and I hope this post helps others 🙂

IMPORTANT: I confidently open up my devices but I must warn you, this voids the warranty. I just shared my experiences and I must also say that I’m not responsible from the damage you can give to your device because of any lack of skill or misapplication or… just anything.

First of all, you must remove the two screws under the mouse, one beneath the sticker:

After removing the hood it should look like this:

Then you should remove the side cover holding the 18g weight inside and cable from the front. Be careful with the two side buttons on the left while removing. You will have something like below. Remove the connector pins to detach the cover and operate easily.

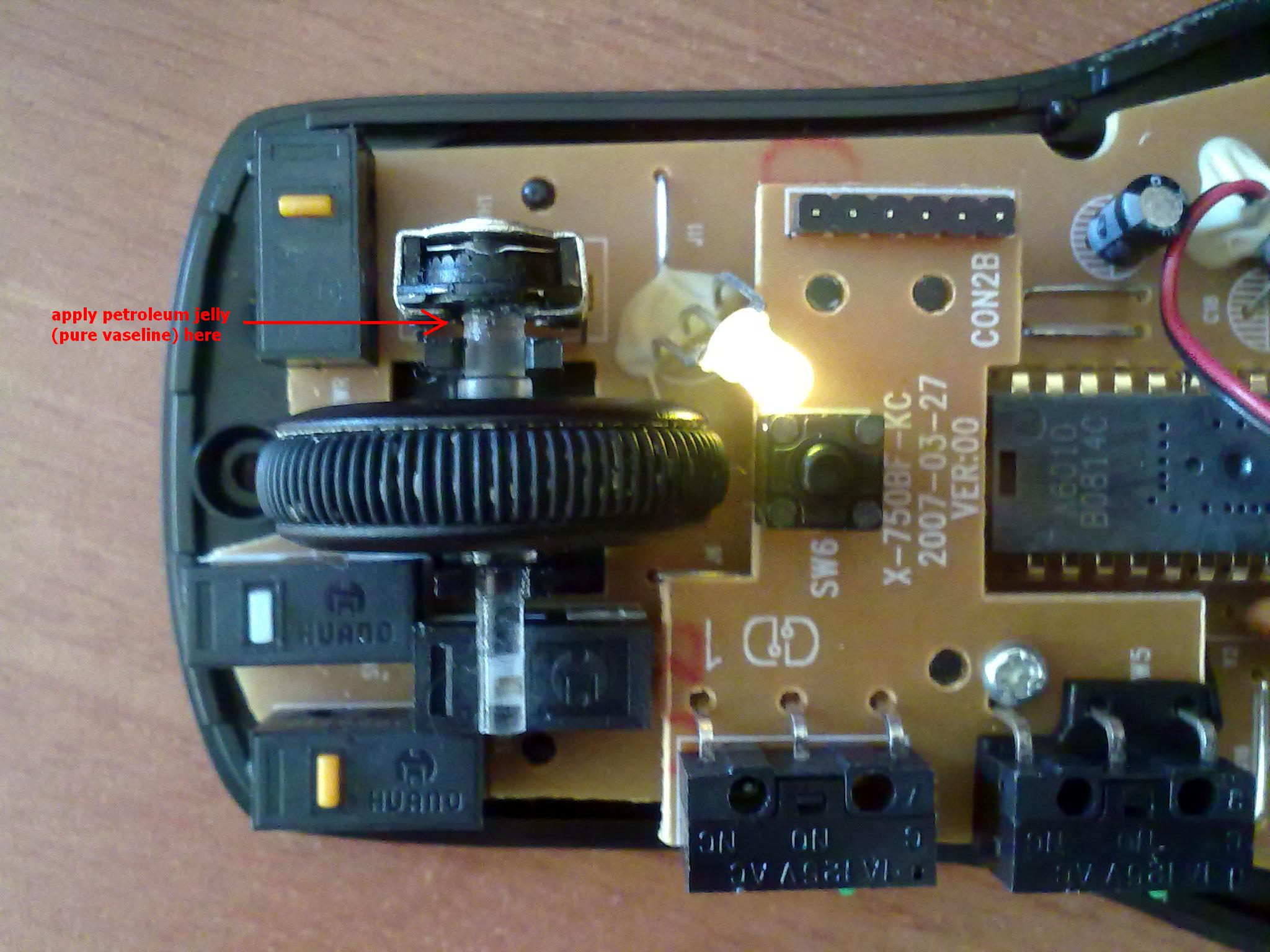

Here we come to the tricky part. You need to pull the wheel (down in this photo) as much as possible to reveal part of the axis in the black jacket that holds it. But be careful not to push its limits and break it. Take some petroleum jelly (pure vaseline) and apply it to the scrollwheel’s axis where it meets the black jacket. I preferred a toothpick. After applying, release the wheel you pulled (down). It goes to where it belongs, inside that black jacket. If it doesn’t, place the axis back to its first position in the jacket and turn the wheel to distribute the lubricant around the axis.

I suggest to test the operation before putting the parts back again. I just connected the pins back without the cover. That’s why you see the LED is on in the photo. If you are not satisfied, apply some more jelly like before and turn the wheel again to distribute it. When you think it’s enough, clean the excessive lubricant around the axis to avoid collecting dust. After that put the parts back together and enjoy 🙂

Leave a comment